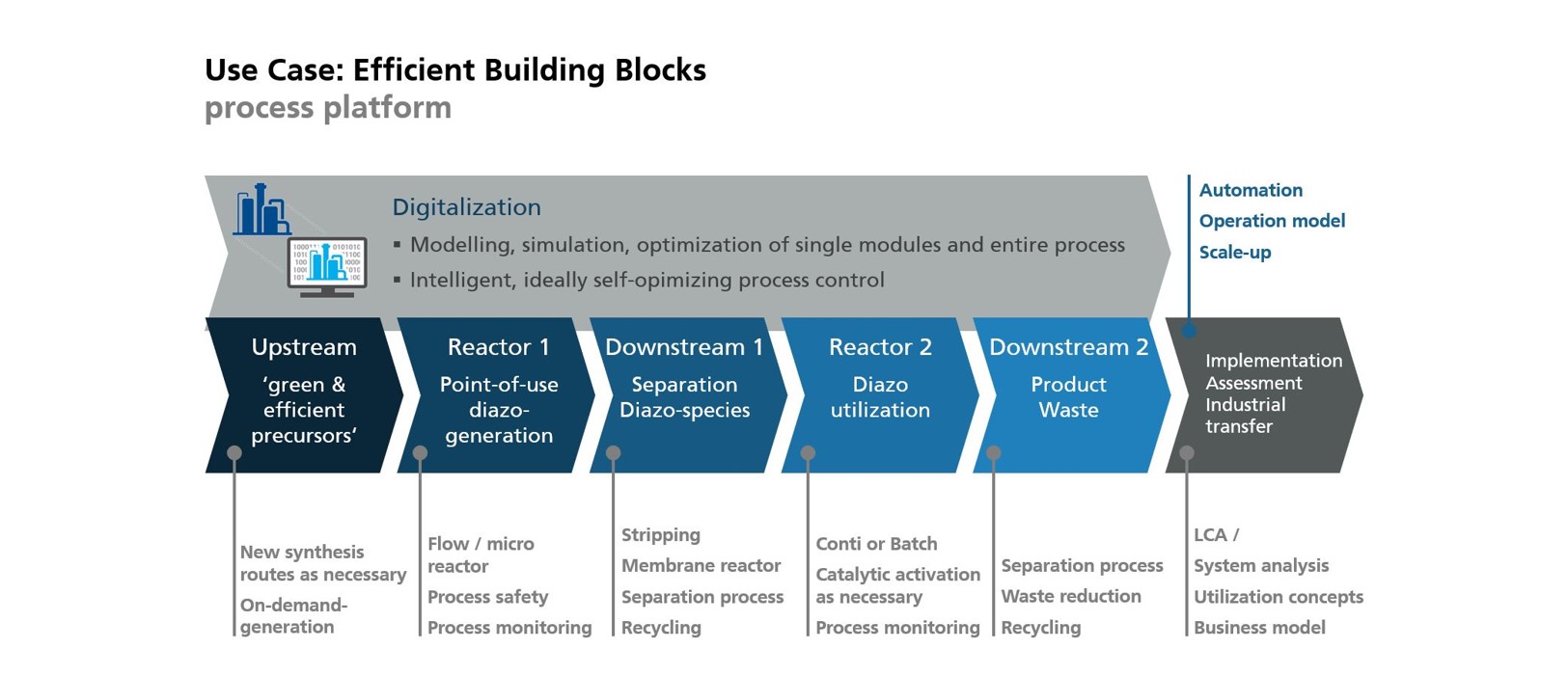

For the demonstrator of efficient building blocks, several partner institutes are jointly developing modular continuous process technology for the point-of-use and on-demand delivery of highly reactive reagents for downstream reaction processes. In the field of fine and specialty chemicals, this enables atom-efficient organochemical syntheses and significantly shortened synthesis paths to be achieved. Waste volumes and energy and solvent consumption can therefore be reduced significantly.

Efficient building blocks

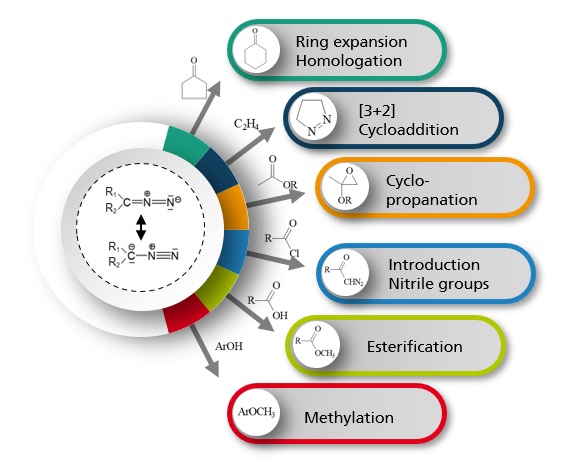

The reactive building blocks considered in this subproject are reagents from the group of diazo compounds that can be used to synthesize high-quality specialty chemicals and precursors - for example for pharmaceutical and agrochemical products - with excellent atomic efficiency, a low number of reaction steps and under extremely mild reaction conditions.

Broad applicability is achieved by a flexible and modular process concept, which allows both the generation of different diazo building blocks (diazo esters, diazonitriles, diazoalkanes) and their use for various subsequent reactions.

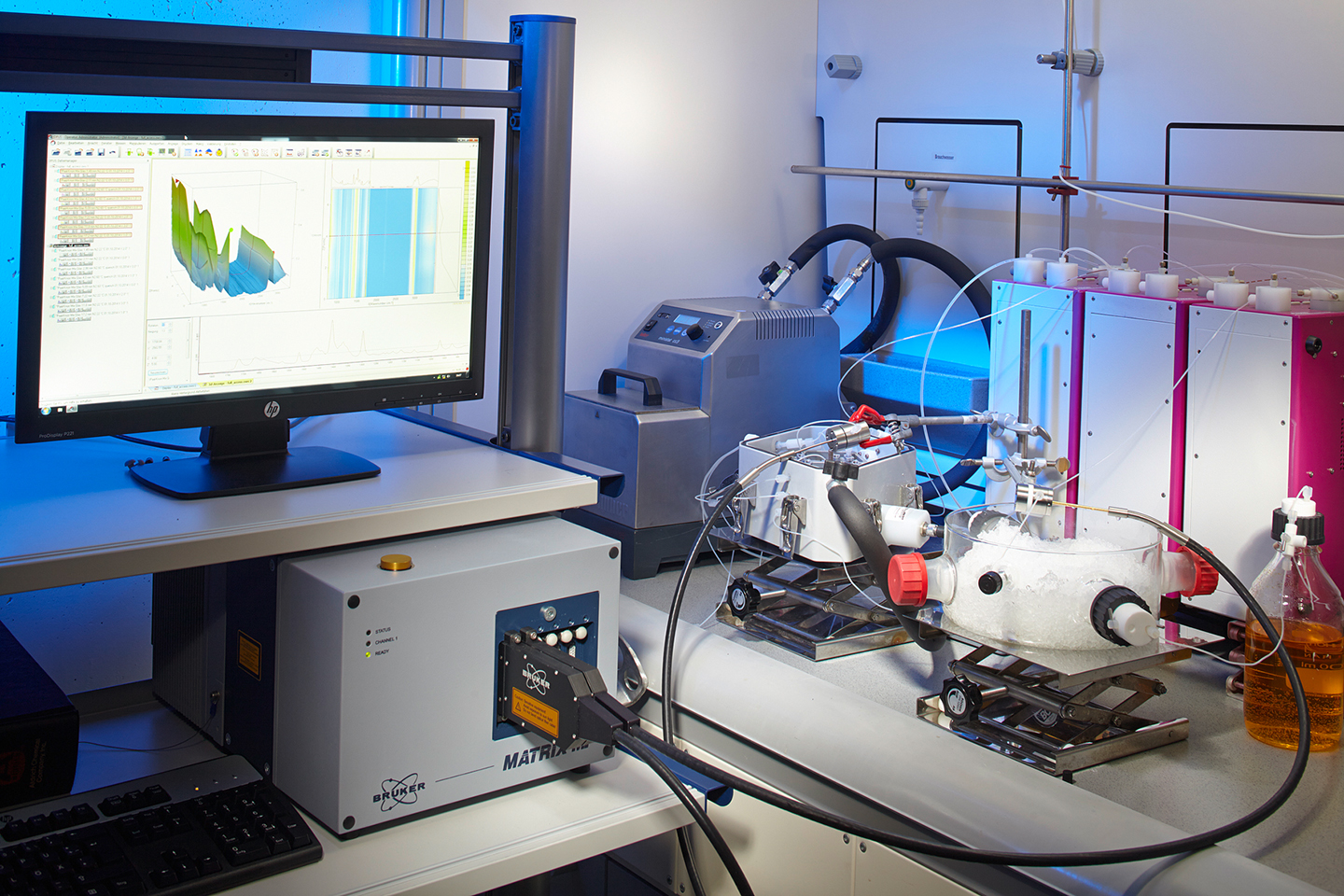

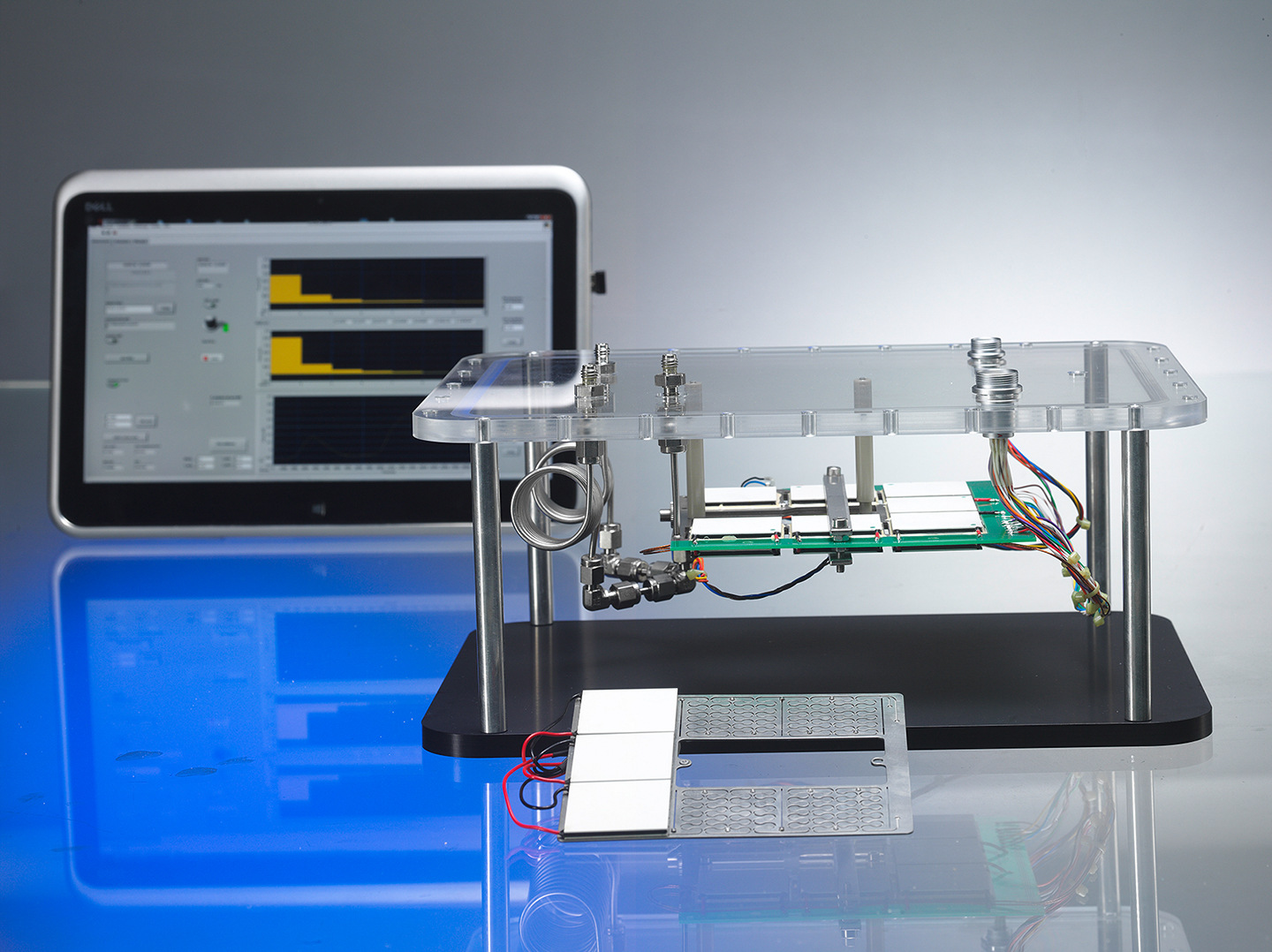

The use of highly reactive compounds poses some fundamental risks and requires a high level of process safety, especially where such processes will later be up-scaled. This is achieved in ShaPID through the application of continuous process control, with micro-process engineering approaches and in-situ conversion of reactive intermediates in a closed reaction system to enable an extremely low reaction volume. Continuous process control is also an important component of process intensification and enables new process windows to be used to overcome the limitations of traditional process concepts, such as the need for reactive intermediates. Microstructured reactors are already used on a small scale for screening reactions and, in combination with spectroscopic and reaction calorimetric process analysis methods, provide the data basis for process design.

In addition to the use of smart process technology for process intensification, virtualization through modeling, simulation and optimization will be established as an essential component for efficient operations management. This starts with the optimization of the apparatus, module and process design in the context of process development, and also includes the virtualization of process operation, to enable intelligent automation and ideally autonomous, self-optimizing process control.

Fraunhofer lighthouse project »ShaPID« – Shaping the Future of Green Chemistry by Process Intensification and Digitalization

Fraunhofer lighthouse project »ShaPID« – Shaping the Future of Green Chemistry by Process Intensification and Digitalization