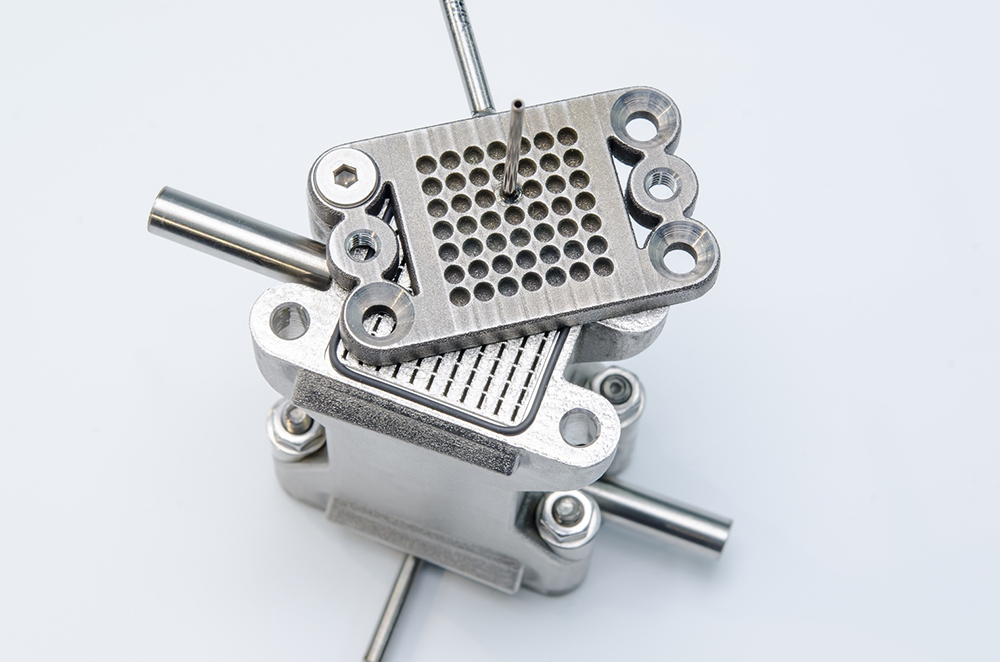

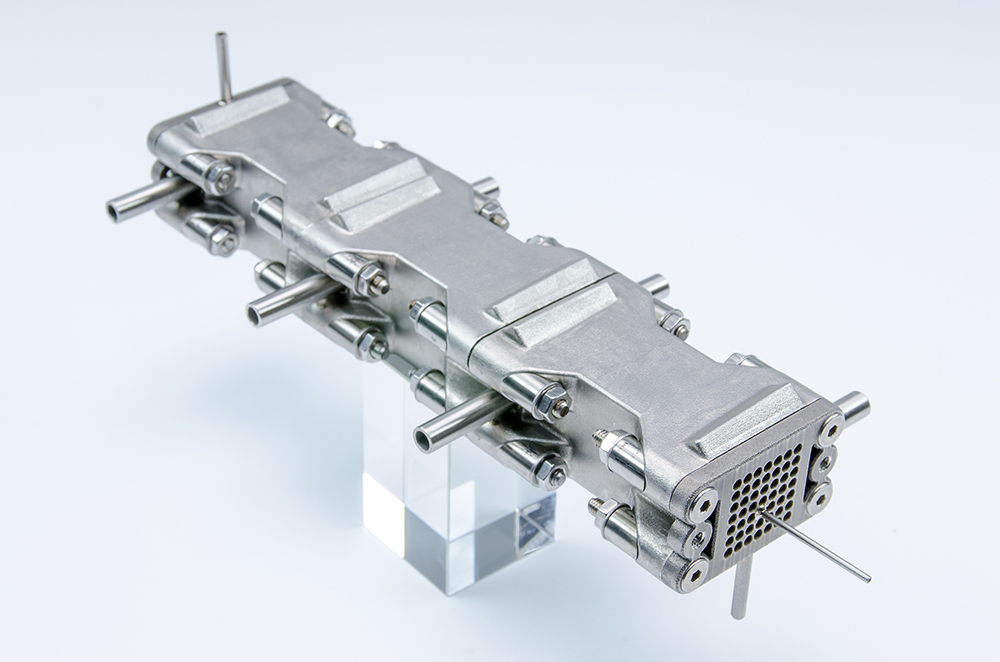

The technology field of smart process technology comprises both the design of chemical processes to render them greener and more efficient, and the corresponding apparatus, reactor and plant technology. Strategically, process intensification is carried out by developing and implementing continuous process technologies (where possible) using customized, micro-process engineering reaction modules and modules for downstream processing. At plant level, the focus is again on modular and scalable plant concepts and components, including their interconnection.

Green chemistry usually requires a joint approach of synthesis chemistry and process engineering concepts. This form of process intensification, which is widely recognized as a strategy to increase the efficiency and flexibility of processing, is a central approach in the ShaPID project. Continuous process control and novel, specifically adapted reactor and reprocessing modules aim to precisely control the conditions of chemical production processes. Technologically, a range of approaches are adopted in the context of process intensification. For example, milli- and microstructured reactors play a major role here in enabling and controlling continuous synthesis processes (flow chemistry). This overcomes the limitations of traditional process concepts, but also enables processes to be redesigned (novel process windows) and intensified. This forms the basis to improve production processes in terms of product properties and energy and resource efficiency. Smart, modular plant concepts also contribute to this. They are also flexible and quickly adaptable production concepts, enabling for example a faster market entry (reduction of time-to-market). This smart process technology thus encompasses developments in continuous process technology, process modules (reactors, upstream/downstream modules, analysis modules) and plants (interconnection and control of the modules, for example in a container infrastructure). The linking of smart process technology with digitization concepts is a further means to increase the efficiency of chemical processes.

Fraunhofer lighthouse project »ShaPID« – Shaping the Future of Green Chemistry by Process Intensification and Digitalization

Fraunhofer lighthouse project »ShaPID« – Shaping the Future of Green Chemistry by Process Intensification and Digitalization