Specifically adapted reactor technologies such as milli- and microstructured reactors enable a precise control of the processing conditions in continuous chemical production processes. By this means, the limitations of conventional equipment are overcome and the basis is laid for process intensification.

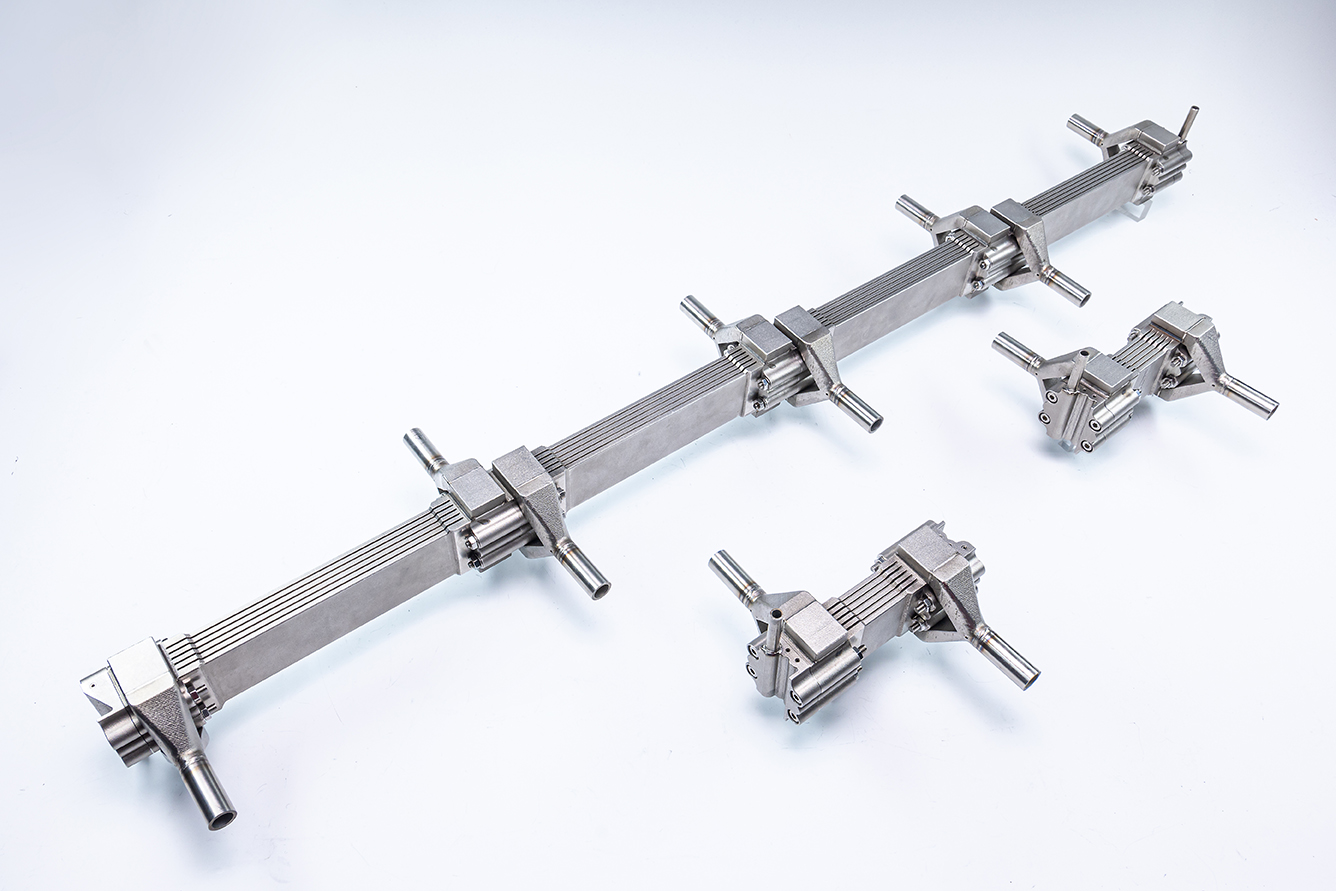

The modular reactor concept followed in the project allows different individual adaptations to specific process needs while also addressing scale-up to achieve higher production rates.

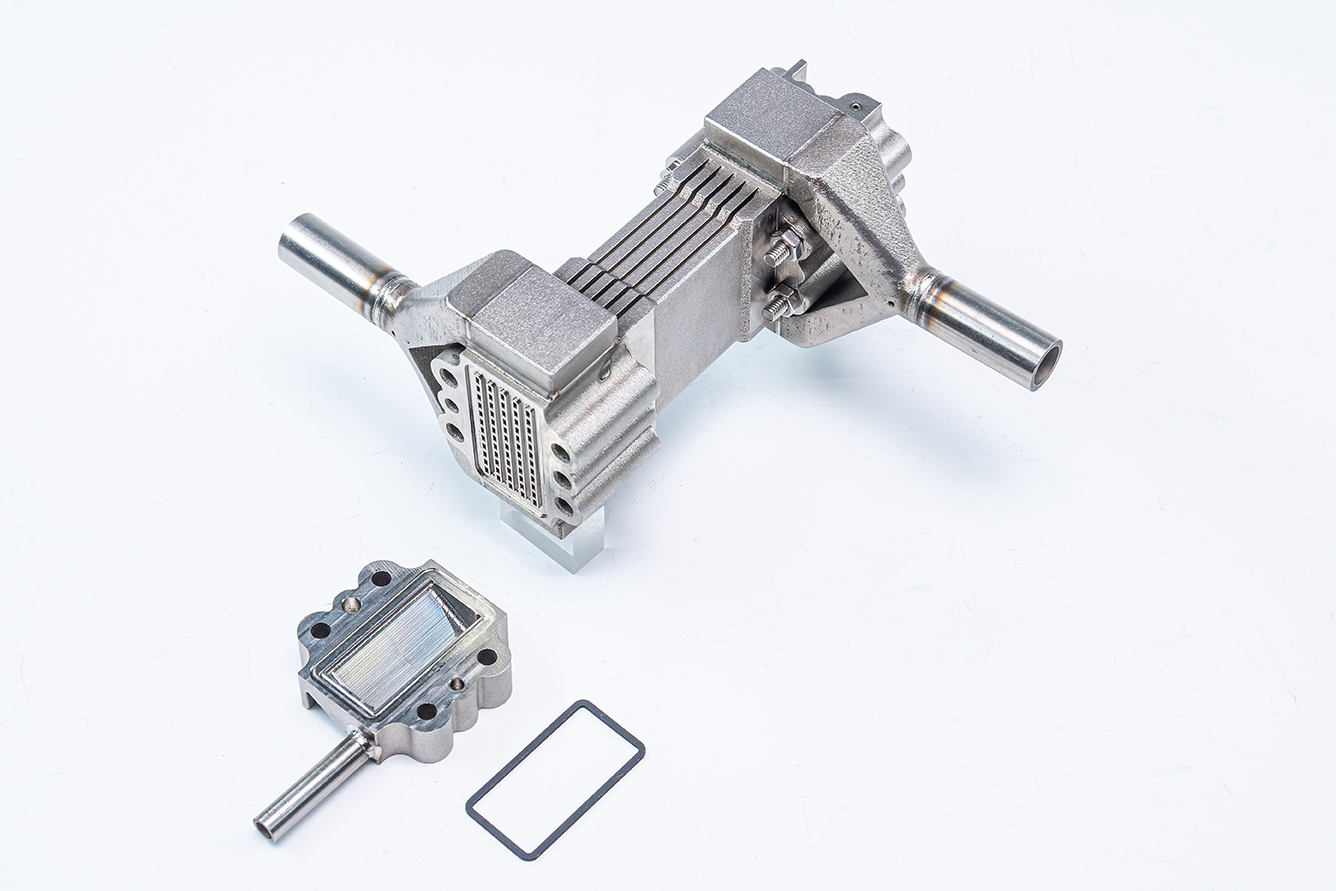

One advantage of the reactor concept is that different modules can be operated either individually or connected in series. The flow path within the modules can be altered by using different distributor plates, thus determining the number of channels in use and their sequence. The design freedom attained by additive manufacturing of these distributor plates plays an essential role.

A wide range of different modules have been assembled to cover both lab-scale investigations and also the piloting trials for different reactive intermediates in the ShaPID demonstrator case “Efficient Building Blocks”, which targets throughput ranges up to several liters per hour and residence times in the range of a few minutes.

Fraunhofer lighthouse project »ShaPID« – Shaping the Future of Green Chemistry by Process Intensification and Digitalization

Fraunhofer lighthouse project »ShaPID« – Shaping the Future of Green Chemistry by Process Intensification and Digitalization